Product description

Sealing sheet Klinger Compensil from manufacturer Klinger is designed primarily for refrigerants, oils and solvents. The plate stands out for its ability to compensate for the inequalities of sealing surfaces, as well as its high compressibility, which is influenced by NBR fibers. Closer parameters in the catalogue sheet.

Table of types

| Name | Thickness [mm] | Width [mm] | Length [mm] | Availability |

| Deska Klinger Compensil 1x1500x2000 | 1 | 1500 | 2000 | on request |

| Deska Klinger Compensil 1,5x1500x2000 | 1,5 | 1500 | 2000 | on request |

| Deska Klinger Compensil 2x1500x2000 | 2 | 1500 | 2000 | in stock |

| Deska Klinger Compensil 3x1500x2000 | 3 | 1500 | 2000 | on request |

Technical documentation

Detailed description

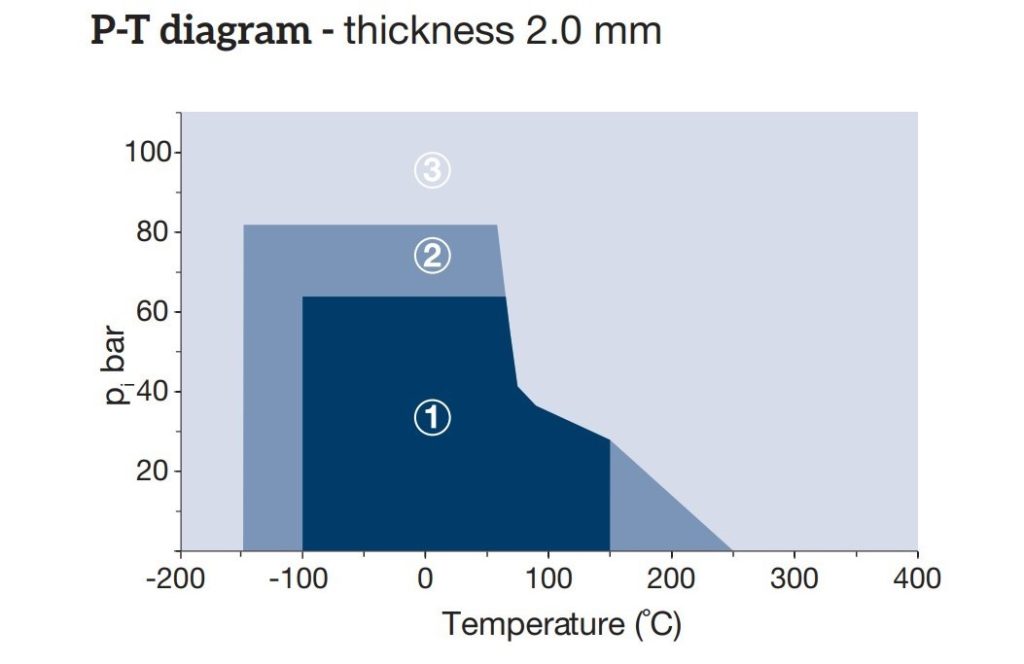

Sealing sheet Klinger Compensil from manufacturer Klinger is designed primarily for refrigerants, oils and solvents. The plate stands out for its ability to compensate for the inequalities of sealing surfaces, as well as its high compressibility, which is influenced by NBR fibers. Based on these capabilities, the sealing plate is able to tighten even with a relatively lower and irregular distribution of tightening pressures. The board consists of mineral fibres, which are connected by the NBR rubber. Closer technical parameters are given in the catalogue sheet. We offer these plates in a standard size semi-finished product of 1500 x 2000 mm in the thicknesses given in the table of variants. The plates can be mechanically fed into a smaller semi-finished product according to the customer’s requirements.

Services-Sealing production

We offer shape CNC sealing of any shape. Making possible according to the drawing (dwg, dxf, pdf) supplied from the customer, or it is possible to distort according to the sample supplied and then agree size and carve. We also offer mechanical circling, stamping and cutting on mechanical machines and a hydraulic press.