Product description

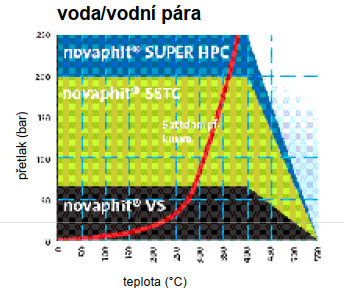

Novaphit SSTC is expanded graphite sealing sheet with stainless steel insert by manufacturer Frenzelit, is designed for higher working parameters and features unique features due to its high-quality expanded graphite. It stands out for its high temperature loadability and resistance to high pressure. Closer parameters in the catalogue sheet.

Table of types

| Name | Thickness [mm] | Width [mm] | Length [mm] | Availability |

| Deska NP SSTC 1x1000x1000 | 1 | 1000 | 1000 | on request |

| Deska NP SSTC 1,5x1000x1000 | 1,5 | 1000 | 1000 | on request |

| Deska NP SSTC 2x1000x1000 | 2 | 1000 | 1000 | in stock |

| Deska NP SSTC 3x1000x1000 | 3 | 1000 | 1000 | in stock |

Technical documentation

Detailed description

Novaphit SSTC is expanded graphite sealing sheet with stainless steel insert by manufacturer Frenzelit, is designed for higher working parameters and features unique features due to its high-quality expanded graphite. It stands out for its high temperature loadability and resistance to high pressure. The plate consists of 2 layers of expanded graphite and 1 insert tahoka interlocking in a compact sealing plate. The prerogative of the Novaphit SSTC board is resistance to almost all organic and inorganic acids, bases, oils and solvents. The stainless steel insert is made of tahoka acid-resistant stainless steel. Sealing from this plate stands out for its universal use in all areas of the chemical industry and covers the full range of application of classical flat seals. Generally speaking, the material is suitable for wide use in extreme conditions with variable loads. Closer technical parameters are given in the catalogue sheet. We offer these boards in a standard size semi-finished product of 1,000 x 1,000 mm in the thicknesses given in the table of variants. The plates can be mechanically fed into a smaller semi-finished product according to the customer’s requirements.

Services-Sealing production

We offer shape CNC sealing of any shape. Making possible according to the drawing (dwg, dxf, pdf) supplied from the customer, or it is possible to distort according to the sample supplied and then agree size and carve. We also offer mechanical circling, stamping and cutting on mechanical machines and a hydraulic press.